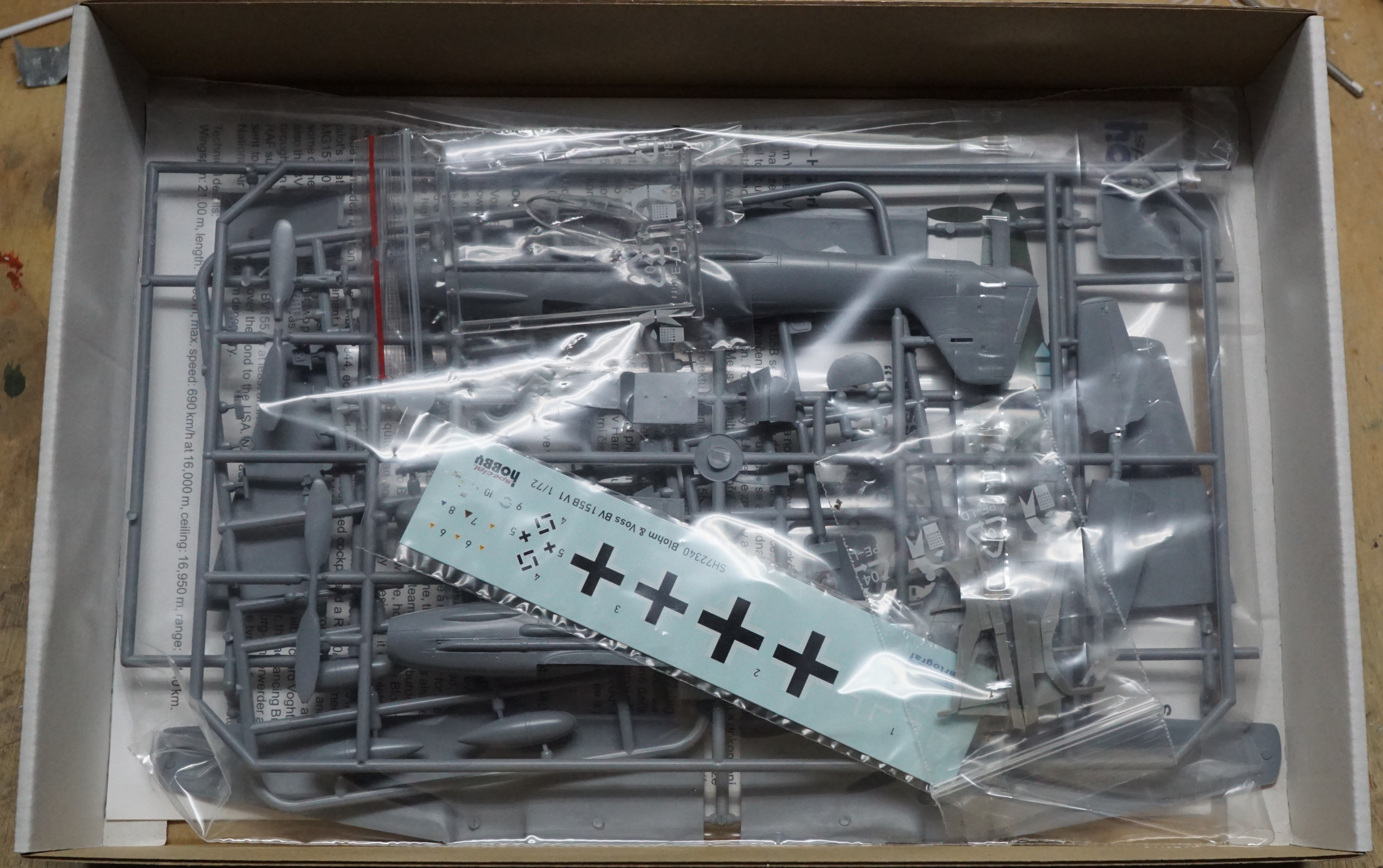

Seems like it's been way more than a month since I started this thread

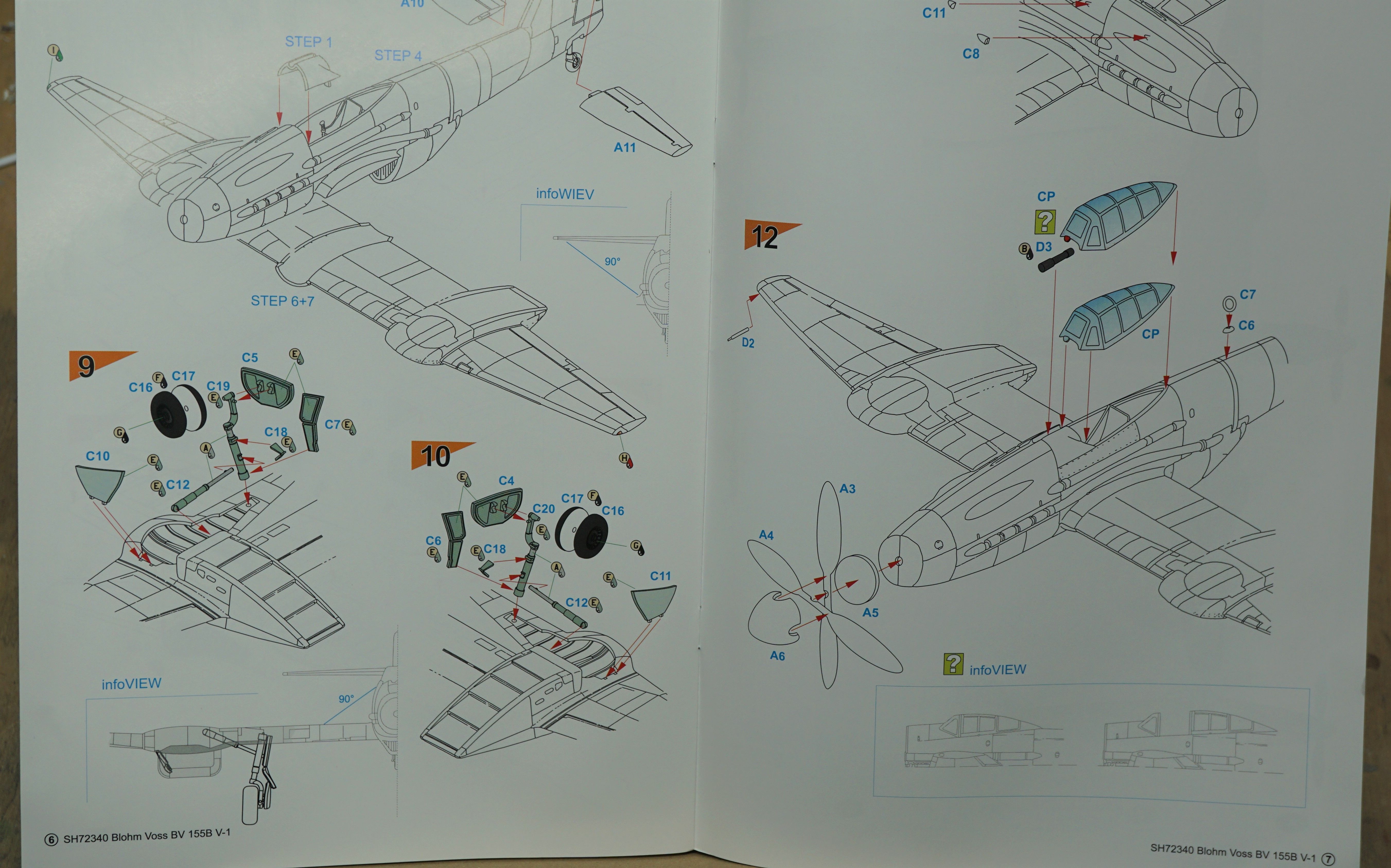

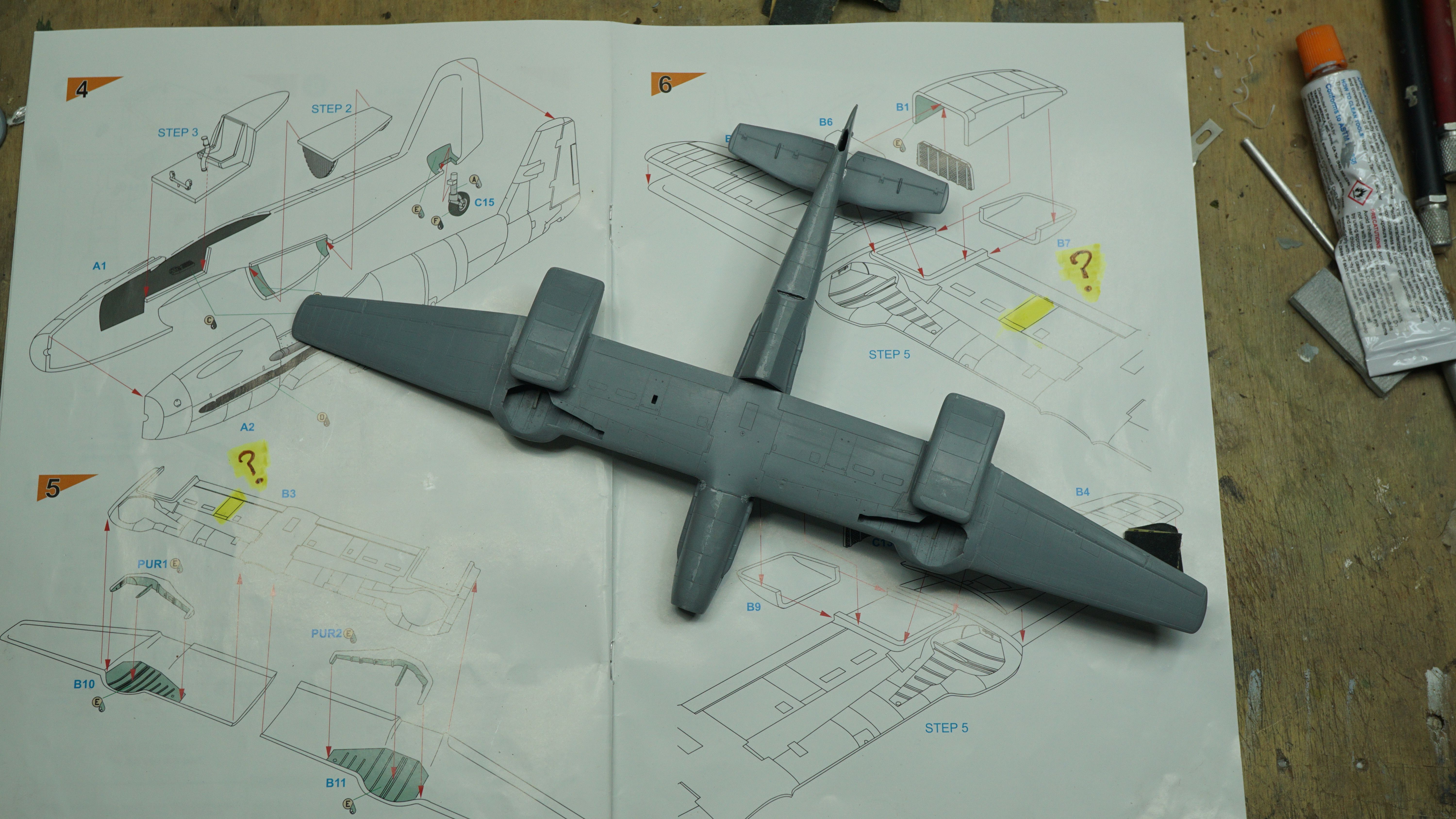

This is one of those builds you have to glue up a quarter to a half inch at a time to keep things lined up as best possible .

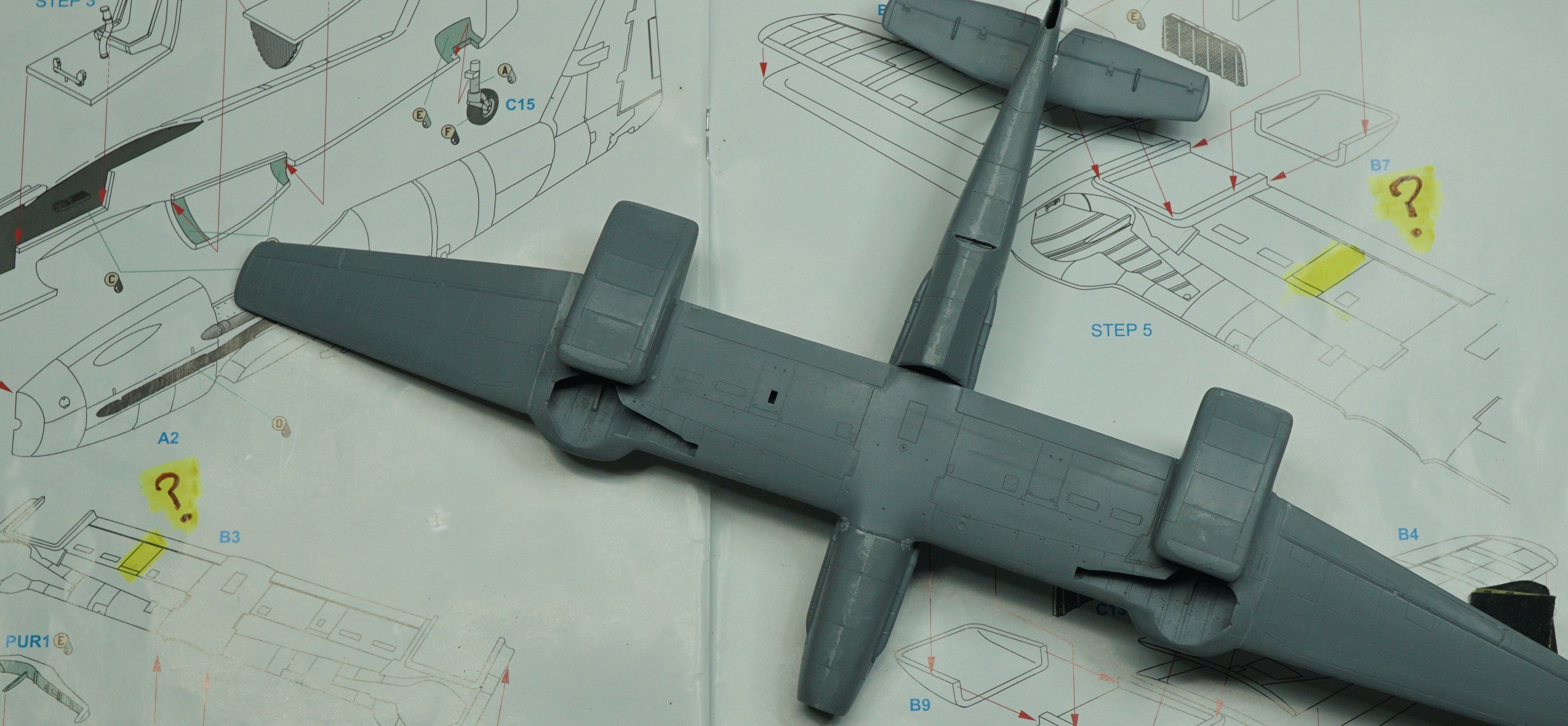

The bulk of this build is going to be putty'n and sanding seams and then restoring panel lines .

It reminds me of the U-2 with these monster-span wings !

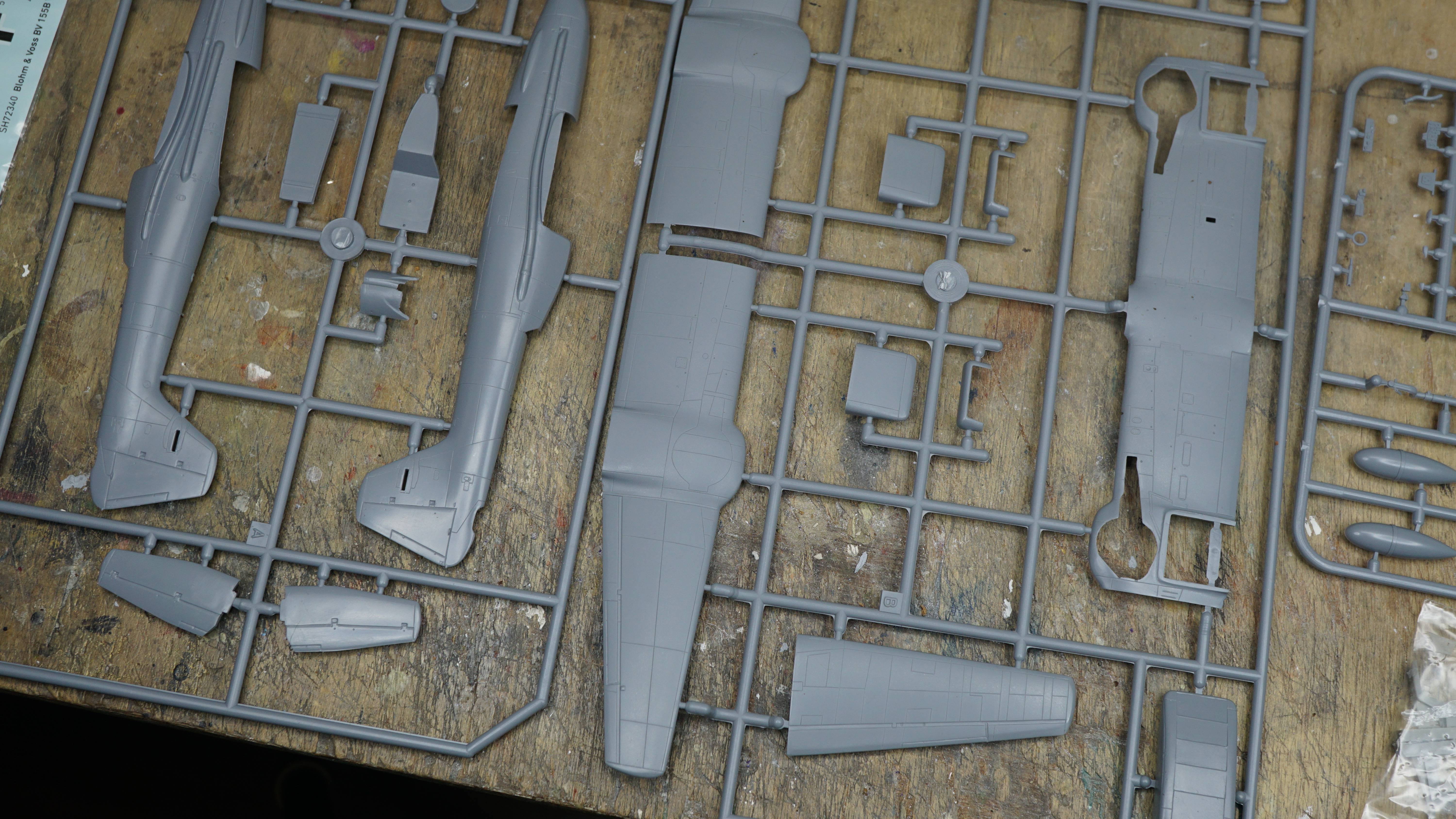

Today will be spent dealing with seams and panel lines ,

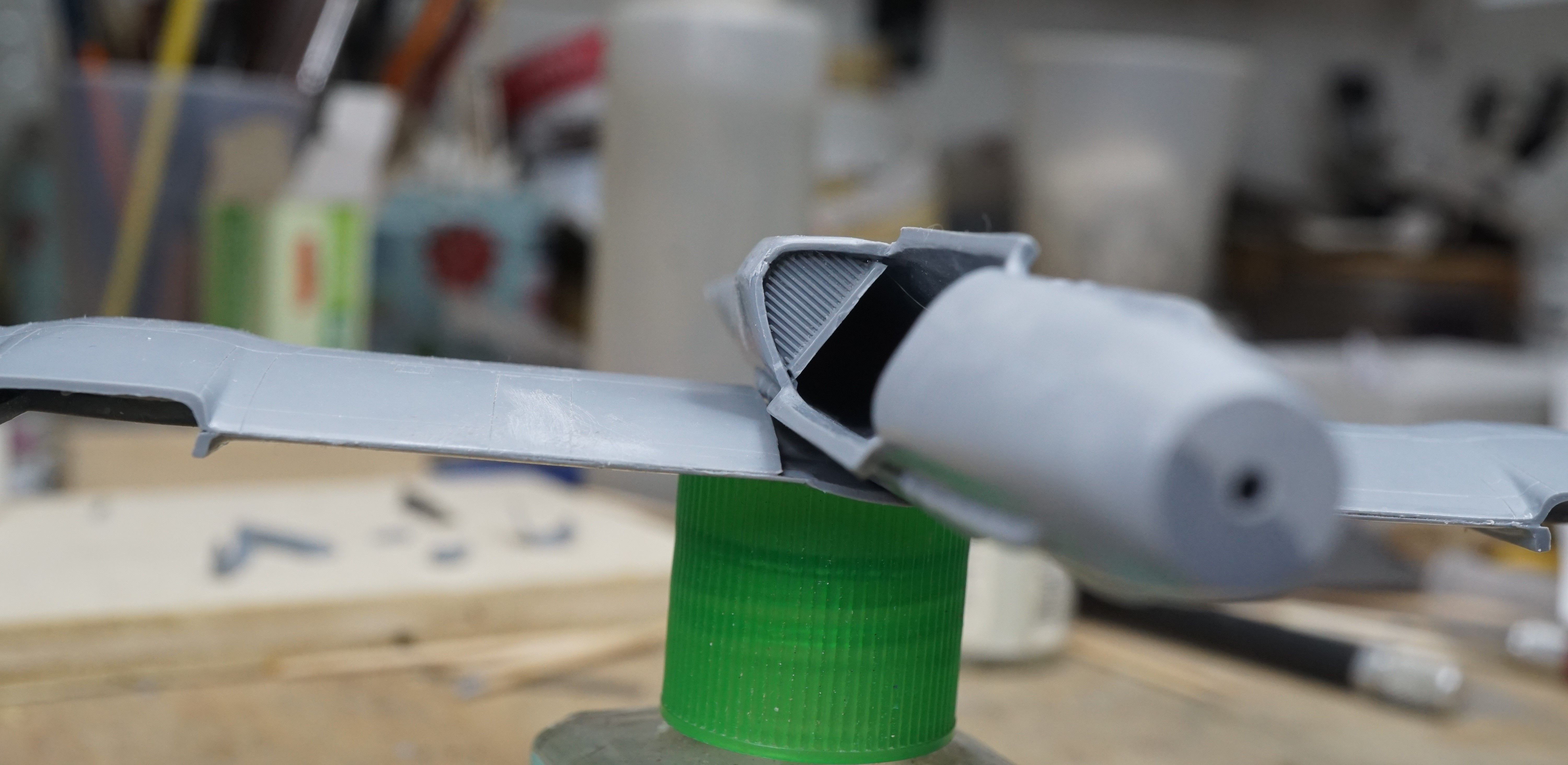

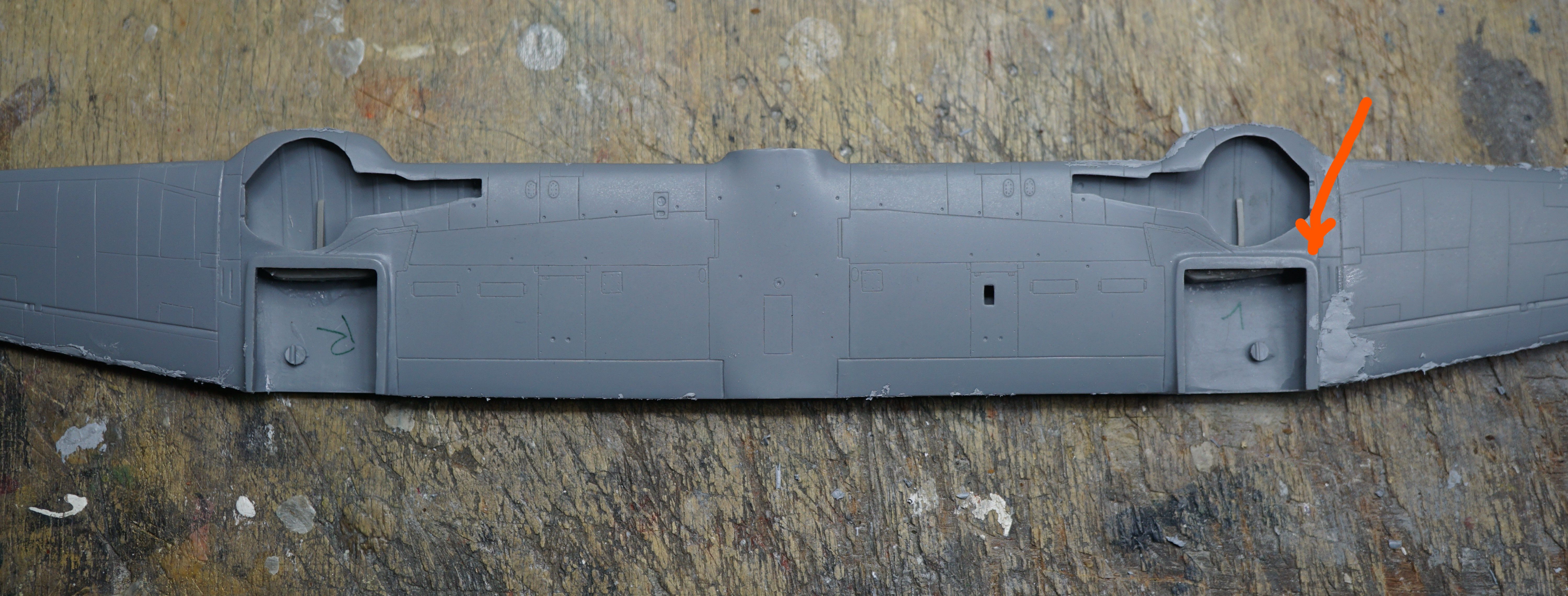

There was major-gappage around this intake for the supercharger .

I added some lacquer putty behind it prior to assembly so I could fill it in from the outside using acrylic medium .

Big improvement but it'll probably need more work after the primer hits it :

I had to remove maybe 3/4 of each positioning tab ( tenon ) from the horizontals to get them to snug up to the vertical , and they will still need putty :

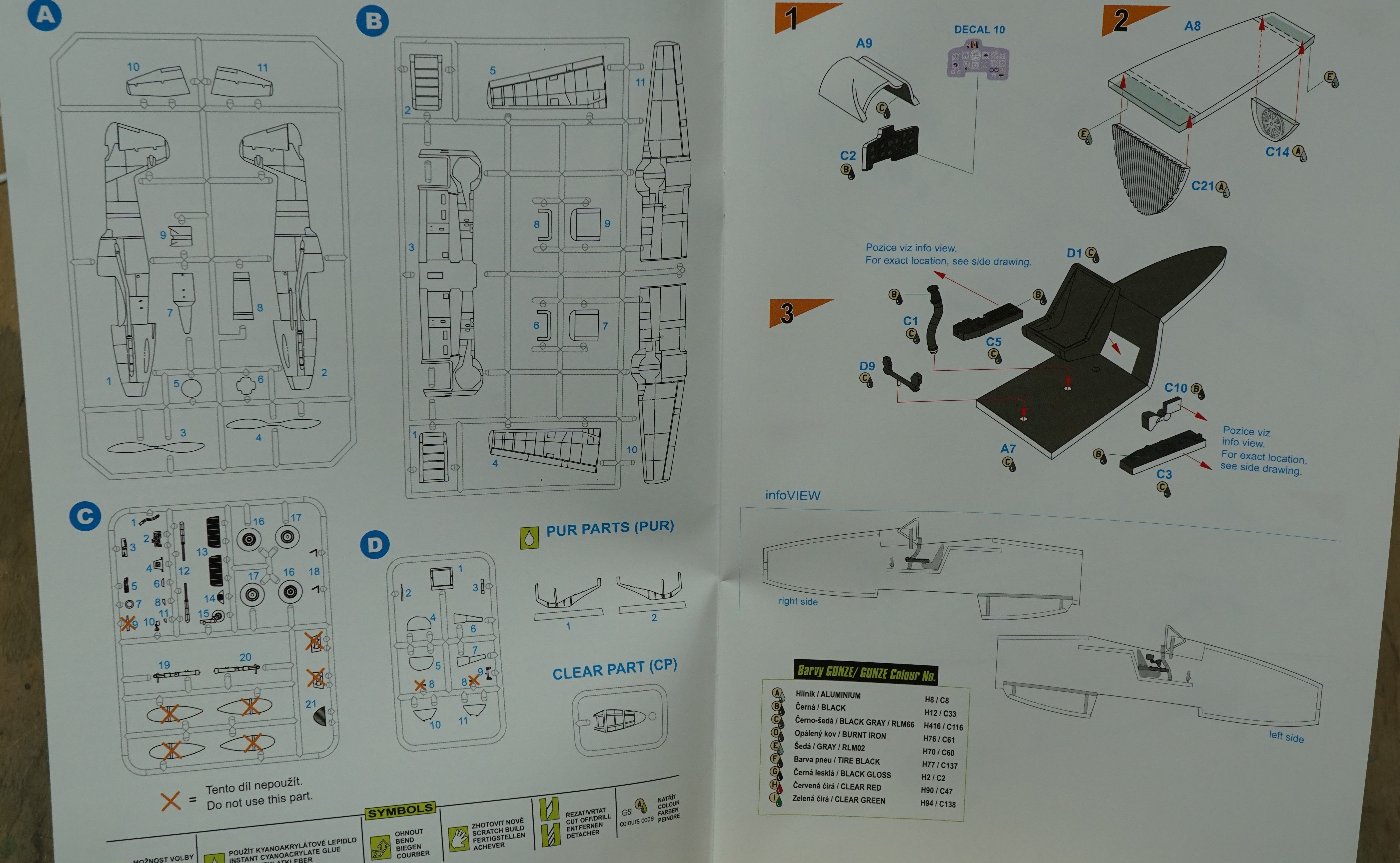

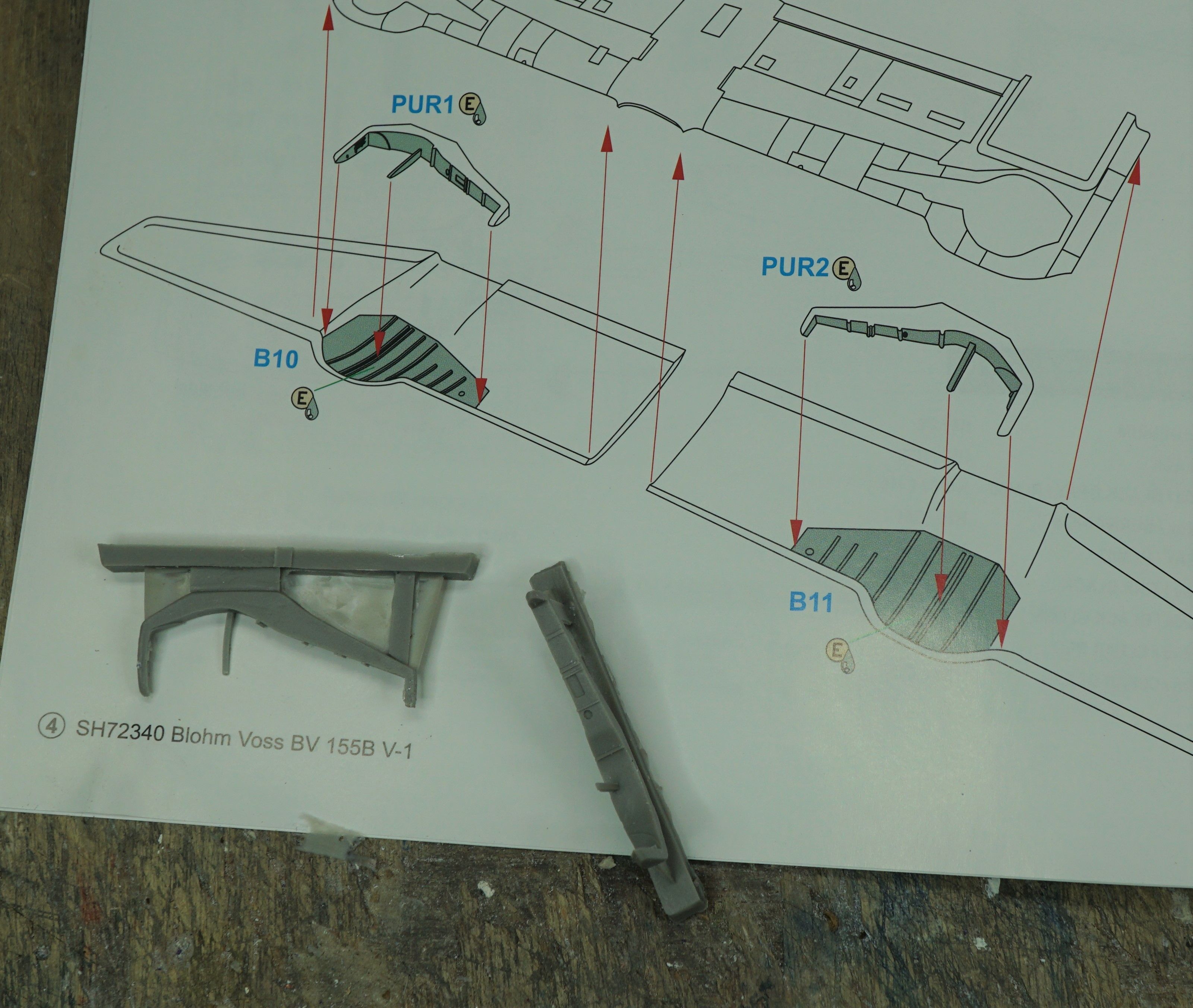

They marked these components for the radiators left and right , but I couldn't see a difference in them at first ,, ,, but the left side is 1/2 mm wider . Maybe .4 mm ,

You can see how the one side of the larger left section is thicker .

Weird .

LOL , who knows what happennated

.. with that extra thickness reciprocated on the wing for that left side :

Weird

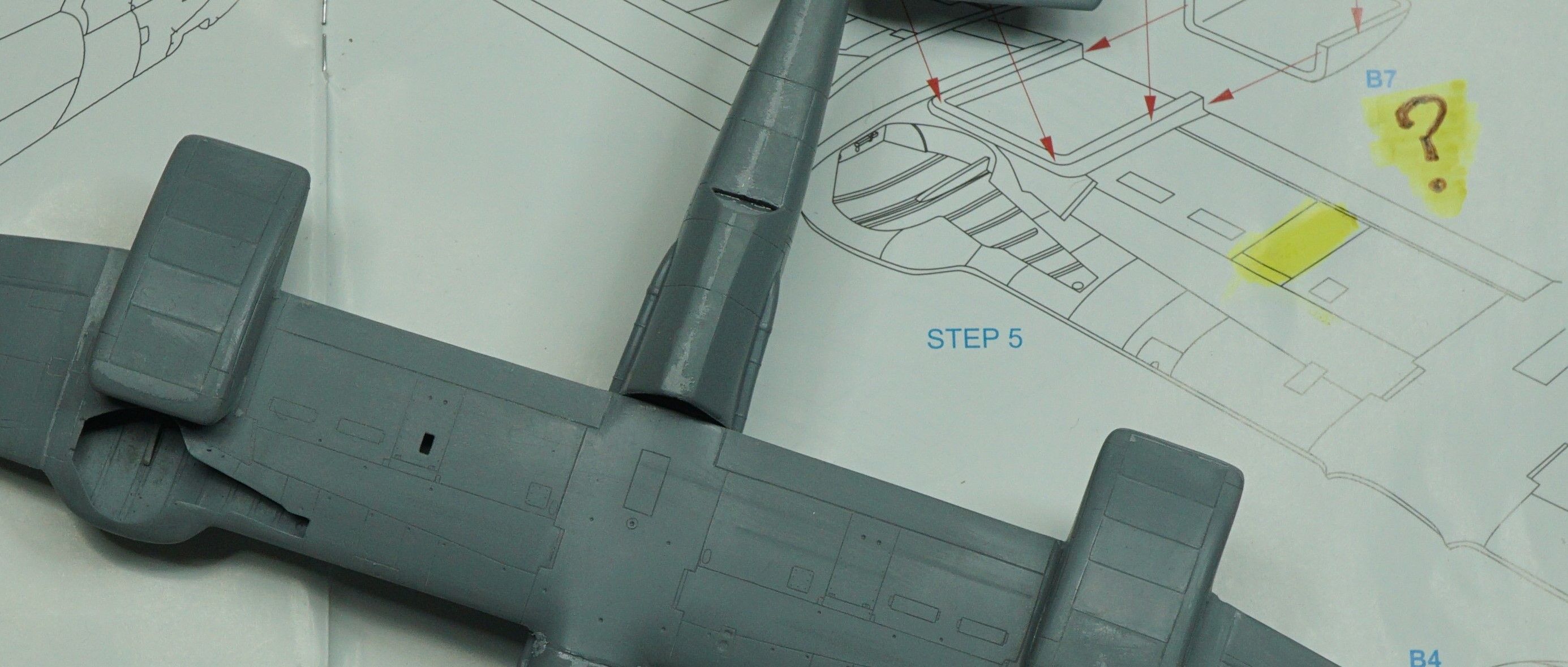

Just like I think they forgot the wheel well bulkheads when they designed the injection molds , I think they forgot a small bulkhead forward of the instrument panel .

The panel goes up into this cowling but it makes 2 points of contact .

Doable but weird :

The kit's plastic is solid & knives , sands and glues well .

So there's that .