Marktastrophe

Well-Known Member

- Joined

- Nov 19, 2021

- Messages

- 371

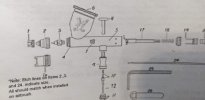

I was sitting here airbrushing with my Paasche Talon (TG1217) when I noticed a bit of air on my knuckles...

I was finishing up with a color anyways, so I flushed it, emptied it, and began to inspect to find that thinner (paint wasn't thin enough to flow back freely?) had backfed into the shaft and trigger area...

Does anyone have any ideas what's happening here?

I was finishing up with a color anyways, so I flushed it, emptied it, and began to inspect to find that thinner (paint wasn't thin enough to flow back freely?) had backfed into the shaft and trigger area...

Does anyone have any ideas what's happening here?