DavidsScaleModels

Well-Known Member

- Joined

- Sep 16, 2022

- Messages

- 165

**************This was listed as 1/48 - Turns out the model is actually a 1/32 scale. Testors mis-printed their box as 1/48!********************

This build is using an old kit made by Testors. Testors was known for doing some of the unique subjects over the years. This is their 1/32 scale H-43B Huskie helicopter. It was originally released in 1961 and re-issued in 1967 to include Viet Nam parts. This version I am building is the final release of the kit in 1998. The Kaman Aircraft H-43B Huskie is a very distinctive helicopter. It uses twin main intermeshing rotors. These were counter-rotating so a tail rotor was not required. It was first flown in 1953 and was in service until the early 1970's. During the Viet Nam was it was utilized as an Air Rescue and Recovery helicopter which were part of the Pacific Air Rescue Center.

I started off working on the interior. The kit does not provide any details. I obtained a lot of reference photos online. The bulkhead between cockpit and crew area was the first part I started detailing. It required mold marks to be filled with putty first. Then using styrene sheets and some photo etch pieces from my spares drawer I added the center post and details to the crew side. I used cloth tape to replicate the padding on the cockpit side. The instrument panel and center console was assembled and detail painted. I used the kit decal for the instrument panel as it matched very well to the reference photos. Next I then test fit the interior to the fuselage and marked where everything lined up so I can detail the insides. The kit also does not include the roof for the crew cabin and the overhead console for the cockpit. I used some sheet styrene shaped for the roof then scribed the panel lines and rivet lines to add detail. The crew area also has an overhead light which I replicated by drilling a hole and installing a clear lens.

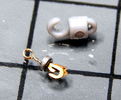

While measuring for the roof I realized the fuselage has two screened intakes molded in for the engine intakes. I cut these out and replaced them with some fine metal screening. There is also a section in the forward post that in the reference photos is open and the kit had these molded closed so I opened these up. Finally I worked on the cockpit seats. The rear of the seats was open so I used sheet styrene to make the backs. After painting them I then made the seatbelts from cloth tape and attached some photo etch buckles. Next I will be working on the overhead console for the cockpit and detailing the interior of the fuselage halves.

You can see all the photos and details from the start in the build log at: https://davidsscalemodels.com/build-log/1-32-kaman-h-43b-huskie-helicopter/

This build is using an old kit made by Testors. Testors was known for doing some of the unique subjects over the years. This is their 1/32 scale H-43B Huskie helicopter. It was originally released in 1961 and re-issued in 1967 to include Viet Nam parts. This version I am building is the final release of the kit in 1998. The Kaman Aircraft H-43B Huskie is a very distinctive helicopter. It uses twin main intermeshing rotors. These were counter-rotating so a tail rotor was not required. It was first flown in 1953 and was in service until the early 1970's. During the Viet Nam was it was utilized as an Air Rescue and Recovery helicopter which were part of the Pacific Air Rescue Center.

I started off working on the interior. The kit does not provide any details. I obtained a lot of reference photos online. The bulkhead between cockpit and crew area was the first part I started detailing. It required mold marks to be filled with putty first. Then using styrene sheets and some photo etch pieces from my spares drawer I added the center post and details to the crew side. I used cloth tape to replicate the padding on the cockpit side. The instrument panel and center console was assembled and detail painted. I used the kit decal for the instrument panel as it matched very well to the reference photos. Next I then test fit the interior to the fuselage and marked where everything lined up so I can detail the insides. The kit also does not include the roof for the crew cabin and the overhead console for the cockpit. I used some sheet styrene shaped for the roof then scribed the panel lines and rivet lines to add detail. The crew area also has an overhead light which I replicated by drilling a hole and installing a clear lens.

While measuring for the roof I realized the fuselage has two screened intakes molded in for the engine intakes. I cut these out and replaced them with some fine metal screening. There is also a section in the forward post that in the reference photos is open and the kit had these molded closed so I opened these up. Finally I worked on the cockpit seats. The rear of the seats was open so I used sheet styrene to make the backs. After painting them I then made the seatbelts from cloth tape and attached some photo etch buckles. Next I will be working on the overhead console for the cockpit and detailing the interior of the fuselage halves.

You can see all the photos and details from the start in the build log at: https://davidsscalemodels.com/build-log/1-32-kaman-h-43b-huskie-helicopter/

Last edited: