Grendels

Active Member

- Joined

- Nov 24, 2009

- Messages

- 9,092

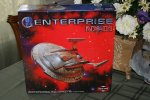

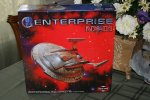

Well, I started on this project a couple of weeks ago, and I finally have found the time to do a little bit of posting. I bought the model off of Ebay as a warm up for the 1/350 1701-A Refit

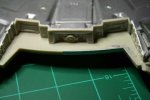

After doing a tape up, I decided to start with the nacelles, they will require the most work, both with lighting, and with seam filling. The directions reccomend that you paint the model first, but I still haven't figured out how to do some that, then go back and fill the seams, keeping the paint one shade. Here is an example of why I am worried about the seams:

I am not sure how to fill this, and keep the textures intact. I won't get started on that for a little while, so I have time to figure it out.

The first thing I did was lay out the parts, and throw some light block paint at it. I used Rust-oleum Metalized paint for this. Two coats, and it has done both light blocking, and put down a very reflective surface. When I get some time, I will post a test photo of this. (Used a green laser to illuminate the saucer section as a test.

Here are photos of the saucer sections with the paint:

If you look closely, there is a broken pin on the above photo, shouldn't hurt the model at all.

I am doing some preliminary painting, mainly with the nacelles, and the warp coils. In the show, the ball ends have a swirl pattern to them, I tried to replicate it:

I used Tamiya clear red, let is set a bit, then brushed on some flat flesh, after drying for a few day, I added more layers of clear red. Gave a good pattern that the camera still does not pick up well. I did some trial runs on a clear plastic box before painting the ball ends just to make sure I was getting the effect I wanted.

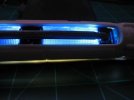

Then I started on the warp coils. A couple coats of tamiya clear blue to start with:

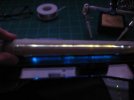

Then I went back and looked at my reference photos (link for reference photos: http://www.ex-astris-scientia.org/scans/nx1.htm ) and found that the outside warp coils have only blue rectangles showing, with the inboard coils showing, blue except where some piping joins up with them. So out came the tape, and I taped it up, applied a few coats of flat black paint. I am still not done with painting these:

The red tape is drafting tape, it is cheap at art supply stores and comes in widths of 1/8 and 1/4 of an inch. Nice when your parts conform to those sizes.

I will post more photos of these when they are done. I still need to put at least one more coat of paint upon them, and then the sides of them need a few coats of black paint. I will update the project as time allows.

After doing a tape up, I decided to start with the nacelles, they will require the most work, both with lighting, and with seam filling. The directions reccomend that you paint the model first, but I still haven't figured out how to do some that, then go back and fill the seams, keeping the paint one shade. Here is an example of why I am worried about the seams:

I am not sure how to fill this, and keep the textures intact. I won't get started on that for a little while, so I have time to figure it out.

The first thing I did was lay out the parts, and throw some light block paint at it. I used Rust-oleum Metalized paint for this. Two coats, and it has done both light blocking, and put down a very reflective surface. When I get some time, I will post a test photo of this. (Used a green laser to illuminate the saucer section as a test.

Here are photos of the saucer sections with the paint:

If you look closely, there is a broken pin on the above photo, shouldn't hurt the model at all.

I am doing some preliminary painting, mainly with the nacelles, and the warp coils. In the show, the ball ends have a swirl pattern to them, I tried to replicate it:

I used Tamiya clear red, let is set a bit, then brushed on some flat flesh, after drying for a few day, I added more layers of clear red. Gave a good pattern that the camera still does not pick up well. I did some trial runs on a clear plastic box before painting the ball ends just to make sure I was getting the effect I wanted.

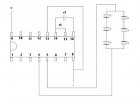

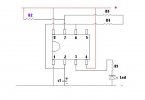

Then I started on the warp coils. A couple coats of tamiya clear blue to start with:

Then I went back and looked at my reference photos (link for reference photos: http://www.ex-astris-scientia.org/scans/nx1.htm ) and found that the outside warp coils have only blue rectangles showing, with the inboard coils showing, blue except where some piping joins up with them. So out came the tape, and I taped it up, applied a few coats of flat black paint. I am still not done with painting these:

The red tape is drafting tape, it is cheap at art supply stores and comes in widths of 1/8 and 1/4 of an inch. Nice when your parts conform to those sizes.

I will post more photos of these when they are done. I still need to put at least one more coat of paint upon them, and then the sides of them need a few coats of black paint. I will update the project as time allows.