trekriffic

Well-Known Member

- Joined

- Jan 6, 2012

- Messages

- 1,023

Did a light test and the dome was TOO green so I thinned the paint with some thinner and it looked much closer to screen accurate. Unfortunately, I discovered something else I hadn't noticed before and that was a crack all the way across the dome. It either happened when I installed the insert or when I was trying to remove it but the dome was ruined. I am now forced to use the clear plastic dome. On the upside I now had the insert free from the dome so tinted some Future with green dye and brushed that on the inside dome-facing surface of the insert. That should look even better than the green paint which I wiped off the underside of the insert.

For now, I have coated the inside surface of the clear dome using Floquil Flat Finish which gives it a milky translucense similar to the translucent white plastic of the original dome.

Here's the new dome with the insert after I brushed on some Future mixed with green dye. I wiped off most of the original green paint from the underside with thinner. I sanded down the red rod just a little and repainted it so it doesn't butt up hard against the inside of the dome. I also sanded the insert's edges so it's not so tight as to crack the dome:

IMG_4459 by trekriffic, on Flickr

I liked the Floquil so much I did the bussard domes too:

IMG_4456 by trekriffic, on Flickr

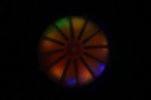

I just loaded it onto a soft brush and sort of flowed it all around inside the dome. The key is to get an even coating. Holding it up to the light it gives you a beautifully translucent effect:

IMG_4458 by trekriffic, on Flickr

This was the same technique I used with my 1/1000 model, outer domes frosted with Floquil Flat and inner dome painted with Tamiya Transparent Orange. The difference this time of course is these bussards will have the rotating fan blades and colored lights:

IMG_1676 by trekriffic, on Flickr

For now, I have coated the inside surface of the clear dome using Floquil Flat Finish which gives it a milky translucense similar to the translucent white plastic of the original dome.

Here's the new dome with the insert after I brushed on some Future mixed with green dye. I wiped off most of the original green paint from the underside with thinner. I sanded down the red rod just a little and repainted it so it doesn't butt up hard against the inside of the dome. I also sanded the insert's edges so it's not so tight as to crack the dome:

IMG_4459 by trekriffic, on Flickr

I liked the Floquil so much I did the bussard domes too:

IMG_4456 by trekriffic, on Flickr

I just loaded it onto a soft brush and sort of flowed it all around inside the dome. The key is to get an even coating. Holding it up to the light it gives you a beautifully translucent effect:

IMG_4458 by trekriffic, on Flickr

This was the same technique I used with my 1/1000 model, outer domes frosted with Floquil Flat and inner dome painted with Tamiya Transparent Orange. The difference this time of course is these bussards will have the rotating fan blades and colored lights:

IMG_1676 by trekriffic, on Flickr