CY343491

Active Member

- Joined

- Apr 5, 2023

- Messages

- 387

Hi all,

I'm using Fengda FD AS-18A compressor, bought it for very cheap price, it works very stable, has a compact size and vibrationless.

It has it's own regulator on it.

I have two spray benches, one have a regulator hanger which eases to adjust and see pressure level when painting, on the other bench i don't have a hanger which i put compressor on my bench.

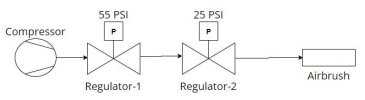

How can i use both of my two benches? I don't want to disassemble my compressor's own regulator, do you think will it work when i adjust compressor's regulator to max. pressure if i use it with external regulator? I mostly use 20-30 PSI and compressor's max. pressure is about 50 PSI. How can i easily bypass compressor's regulator without disassembling, i think it's the best way to bypass the internal regulator somehow?

I'm using Fengda FD AS-18A compressor, bought it for very cheap price, it works very stable, has a compact size and vibrationless.

It has it's own regulator on it.

I have two spray benches, one have a regulator hanger which eases to adjust and see pressure level when painting, on the other bench i don't have a hanger which i put compressor on my bench.

How can i use both of my two benches? I don't want to disassemble my compressor's own regulator, do you think will it work when i adjust compressor's regulator to max. pressure if i use it with external regulator? I mostly use 20-30 PSI and compressor's max. pressure is about 50 PSI. How can i easily bypass compressor's regulator without disassembling, i think it's the best way to bypass the internal regulator somehow?