Papermodder

Modeller in both Plastic and Paper Card

- Joined

- Jan 2, 2013

- Messages

- 1,224

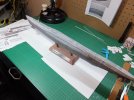

Tonight's update.

The Pivot supports for the rear dive planes were completed and installed around the props to the dive planes.

The next thing was to cut out the support frame for the rudders and shape and colour the edges.

Here the braces for the dive planes and the rudders are installed.

After these dried, then on to install some hull plate strap detail to the rear of the hull, as was done to the bow earlier.

Just another view.

Tomorrow we will move on to the forward dive planes.

I've been heavily documenting this build, trying to show the stages in producing a model of this genre. I hope you are enjoying the journey.

Jim

The Pivot supports for the rear dive planes were completed and installed around the props to the dive planes.

The next thing was to cut out the support frame for the rudders and shape and colour the edges.

Here the braces for the dive planes and the rudders are installed.

After these dried, then on to install some hull plate strap detail to the rear of the hull, as was done to the bow earlier.

Just another view.

Tomorrow we will move on to the forward dive planes.

I've been heavily documenting this build, trying to show the stages in producing a model of this genre. I hope you are enjoying the journey.

Jim