trekriffic

Well-Known Member

- Joined

- Jan 6, 2012

- Messages

- 953

Here are the latest photos.

Engine vent wiring:

Three 3mm red LEDs wired in series with 10 ohm resistor.

Engine vent light test:

Engine vent covers:

Clear plastic covers cut from thin clear sheet styene then press fit (they fit snugly) then glued with Micro Kristal Klear. The covers were needed to give the stern engine vent decals a flat surface to be applied to.

Dymo label tape:

The Dymo tape serves as a guide for the scribing tool I used to cut an access panel out of the lower hull.

Busby Birdwell in his pilot seat:

Clear dome was attached to cockpit with Krestal Klear and lit up. The light was bright enough to shine thru the white plastic and illuminate the instrument panel from below.

Ceiling panel wiring:

LEDs posiitoned to be directly above cabin seats. Two forward LEDs wired in series with 150 ohm resistor. Rear LED will be in series with cockpit light.

Upper and lower hull halves:

The cabin ceiling is painted Bright Blue to match the rest of the interior. The negative battery lead is wired to the pushbutton switch which has been glued and packed with Tamiya epoxy putty to ensure it will NEVER break loose. The battery is held in place to the upper hull half with a velcro tie strap.

Next up is decaling the instrument panel in the bow of the ship and gluing Erica Cane, Jonathan Kidd, and Guru into their seats before gluing the seats to the cabin floor. Then I'll finish wiring up the LEDs to the negative pushbutton and positive battery leads before sealing the hull up.

As always, thanks for following along. Comments appreciated!

Engine vent wiring:

Three 3mm red LEDs wired in series with 10 ohm resistor.

Engine vent light test:

Engine vent covers:

Clear plastic covers cut from thin clear sheet styene then press fit (they fit snugly) then glued with Micro Kristal Klear. The covers were needed to give the stern engine vent decals a flat surface to be applied to.

Dymo label tape:

The Dymo tape serves as a guide for the scribing tool I used to cut an access panel out of the lower hull.

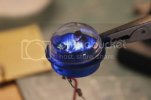

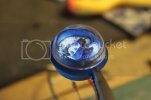

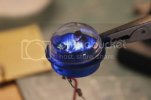

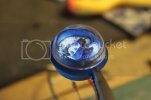

Busby Birdwell in his pilot seat:

Clear dome was attached to cockpit with Krestal Klear and lit up. The light was bright enough to shine thru the white plastic and illuminate the instrument panel from below.

Ceiling panel wiring:

LEDs posiitoned to be directly above cabin seats. Two forward LEDs wired in series with 150 ohm resistor. Rear LED will be in series with cockpit light.

Upper and lower hull halves:

The cabin ceiling is painted Bright Blue to match the rest of the interior. The negative battery lead is wired to the pushbutton switch which has been glued and packed with Tamiya epoxy putty to ensure it will NEVER break loose. The battery is held in place to the upper hull half with a velcro tie strap.

Next up is decaling the instrument panel in the bow of the ship and gluing Erica Cane, Jonathan Kidd, and Guru into their seats before gluing the seats to the cabin floor. Then I'll finish wiring up the LEDs to the negative pushbutton and positive battery leads before sealing the hull up.

As always, thanks for following along. Comments appreciated!