That's a lot of cutting in 2 mm styrene so I switched to the scroll saw :

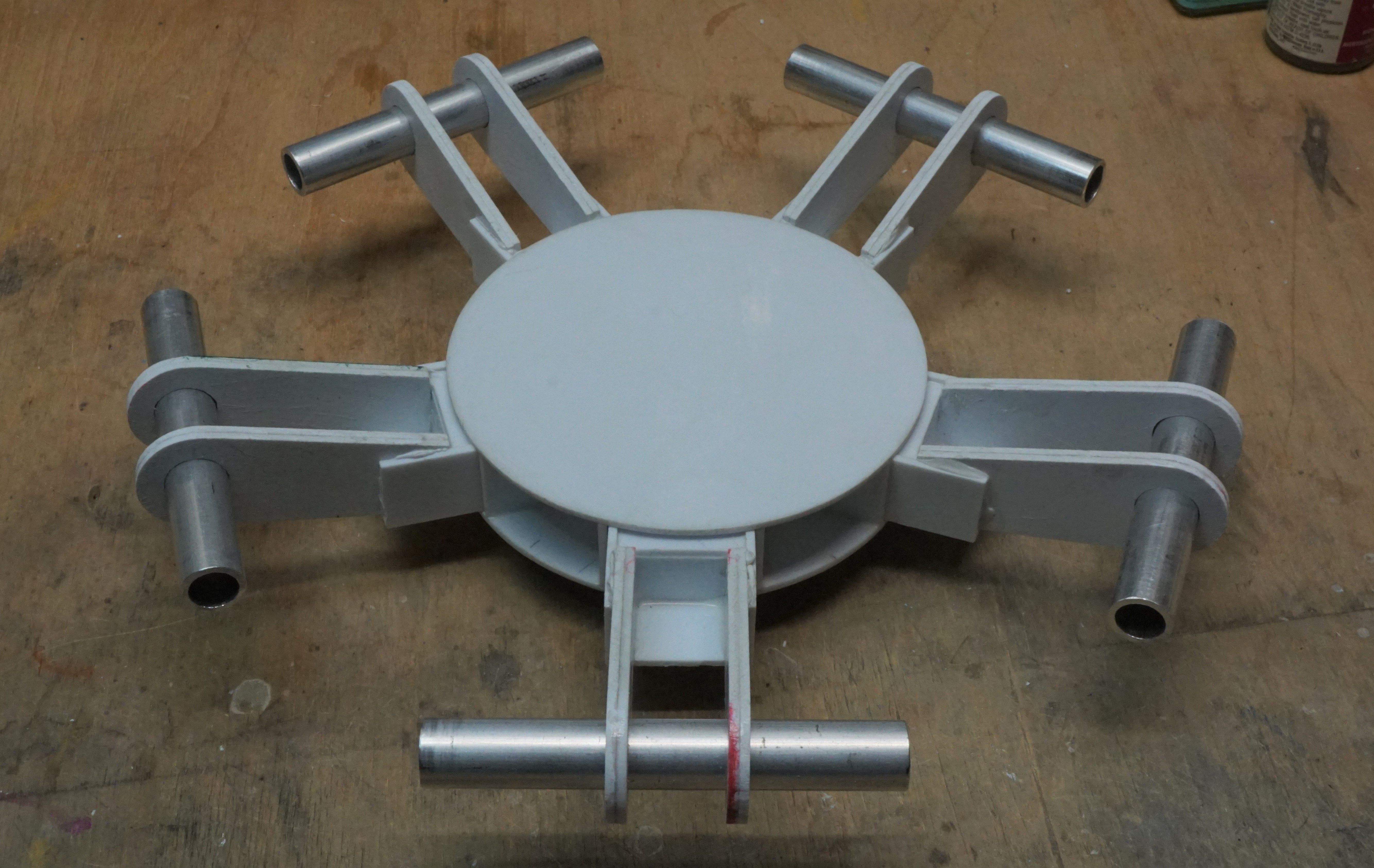

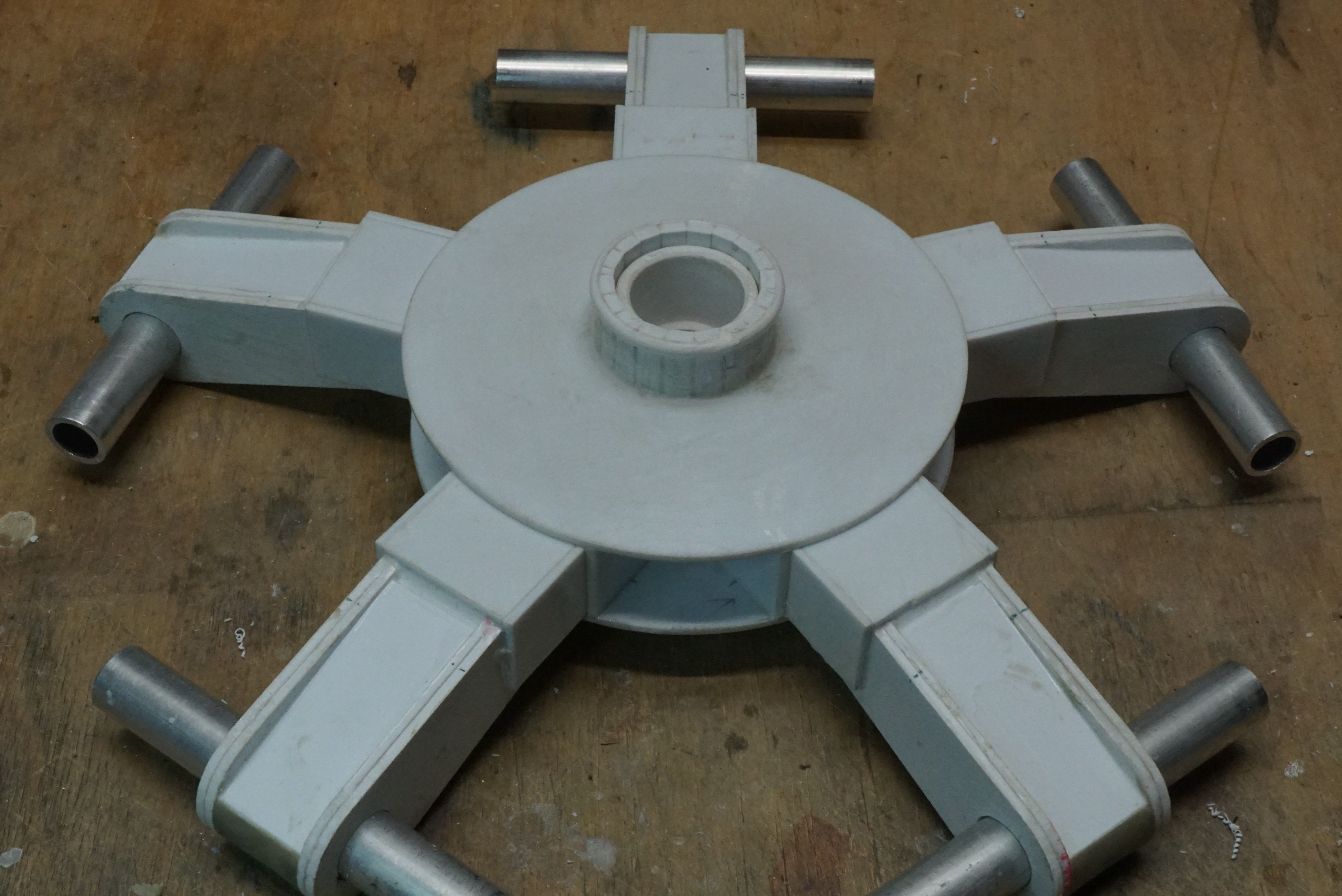

Roughed-out with the scroll saw , then finished with sanding sticks using a jig to ensure exact duplication :

So , at the beginning of all this I checked the O.D. of the aluminum with this drafting template conveniently hanging next to the bench ,

Imagine my delight when the tube , which I guess we're calling 3/8 pipe now , wouldn't fit into the hole .

The first drill bit I had in the press had way too much run-out ( probably why it was in the

Bad-Bits-Bin

) so I switched it out with a different brad point .

I figured I grabbed a 31/64 bit or something .... . Nope.

It's actually .516 inches ( 13.13 mm ) O.D.

Swell .

Terribly inconvenient .

I used that little jig to slice that 2 hundredth's of an inch out of the way using a sharp #11 blade .

Time Consuming .

glad I'm not working with 1/2 inch aluminum plate