Burnette12

New Member

- Joined

- May 18, 2023

- Messages

- 6

Hi everyone,

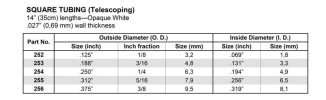

I am building a small prototype for a product I'm developing and could use some help. I'm using Evergreen's Square Polystyrene tubing to create a telescopic assembly. My issue I'm running into is how to keep the assembly together without pulling the sections apart. I've been trying to figure out a way to flare the top and bottom of each section or add some type of flange but I've not found a good way to do this.

For reference a small metal radio antenna that expands and collapses is a good example of what I'm looking for. Force is applied to extend it and force is applied to contract it. When pulled the sections move one at a time until they catch a groove which keeps it from moving any further and then the next section comes through until you reach the end. There are multiple sections of tube with various diameters but they all work together as one mechanism.

If anyone has any advice or experience with something like this I would love some help. Thank you all so much!

I am building a small prototype for a product I'm developing and could use some help. I'm using Evergreen's Square Polystyrene tubing to create a telescopic assembly. My issue I'm running into is how to keep the assembly together without pulling the sections apart. I've been trying to figure out a way to flare the top and bottom of each section or add some type of flange but I've not found a good way to do this.

For reference a small metal radio antenna that expands and collapses is a good example of what I'm looking for. Force is applied to extend it and force is applied to contract it. When pulled the sections move one at a time until they catch a groove which keeps it from moving any further and then the next section comes through until you reach the end. There are multiple sections of tube with various diameters but they all work together as one mechanism.

If anyone has any advice or experience with something like this I would love some help. Thank you all so much!